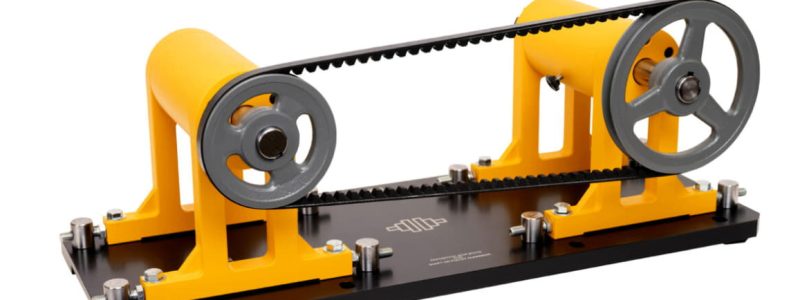

In the realm of industrial machinery maintenance, ensuring that belts and pulleys operate in perfect harmony is crucial for prolonging equipment life and enhancing efficiency. The alignment of these components plays a significant role in preventing premature wear and avoiding unexpected breakdowns. This is where belt alignment tools come into play. Here we’ll guide you through the process of selecting the most appropriate tools for this vital maintenance task.

Understanding the Basics

Misaligned belts can lead to increased friction and heat, resulting in energy losses and potential damage to both the belt and the machinery. By choosing the right alignment solutions, you ensure the smooth operation of your equipment, which can significantly save on repair costs and energy consumption.

Types of Alignment Instruments

There are several types of devices designed to aid in the alignment process, each with its unique features and applications. Laser-based systems are among the most popular due to their high precision and ease of use. These systems project a laser beam onto targets mounted on the pulleys, allowing technicians to quickly identify and correct misalignment. Other tools might use alternative methods such as dial indicators or even simple visual aids, but laser systems usually provide the fastest and most accurate results.

Key Factors to Consider

When selecting the right tool for your needs, there are several factors to take into account:

Precision

The accuracy of the tool is paramount. Look for systems that offer high-precision measurements to ensure that your belts and pulleys are perfectly aligned.

Ease of Use

Consider how user-friendly the system is. Tools that are complicated to set up or require extensive training might not be the best choice for every situation. Opt for instruments that offer straightforward operation and clear instructions.

Durability

Industrial environments can be harsh, so it’s important to choose a tool that is robust and can withstand the conditions in which it will be used. Look for products made from durable materials that have a proven track record of reliability.

Cost

Finally, consider the cost of the instrument and weigh it against the benefits it provides. While more expensive tools might offer additional features or higher precision, ensure that these aspects are necessary for your specific application.

Conclusion

Selecting the right belt alignment tools is a critical decision that can have a significant impact on the efficiency and longevity of your machinery. By understanding the basics of belt alignment, familiarizing yourself with the different types of tools available, and considering key factors such as precision, ease of use, durability, and cost, you can make an informed choice that meets your specific needs.