Modern manufacturing allows manufacturers to create vast quantities of goods in a very short period of time with the help of shaft alignment equipment. This not only makes items more accessible to customers all across the globe but also fosters more fair pricing by cutting manufacturing costs. Manufacturing has enabled significant technical and medical advances and has contributed to the present civilization we all enjoy. However, in order for manufacturing to work well, machines must be configured to accurate dimensions that facilitate the constant manufacture of duplicate things. When machines are misaligned, a slew of issues arises, including greater costs, maintenance challenges, and poor product quality.

How Precise Alignment May Assist You

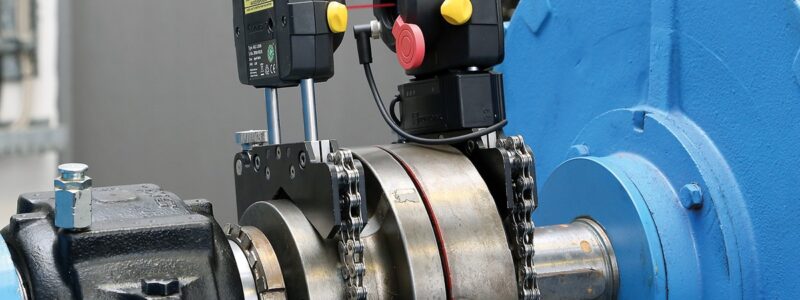

Precise alignment laser is an essential component of all industrial applications that rely on accurate measurements to perform effectively. Alignment is often capable of resolving a wide range of issues, including saggy edges, uneven thickness, poor web tracking, and web breakage. When factories want the precise alignment to improve quality and efficiency, they often depend on laser trackers.

Laser Alignment In Industry

A laser tracker is a portable device that measures and/or inspects in a spherical volume with a range of up to 60 meters. The device’s adaptability allows the operator to examine items of varied sizes, whether static or in motion. Laser trackers are ideal for many kinds of manufacturing sectors, including automotive, aerospace, heavy industrial, and everything in between. They are efficient, accurate, and trustworthy. In the end, if precision is important, shaft alignment equipment is the best option.

Reliable, Repeatable Precision

One of the most valuable characteristics of an industrial alignment laser is its ability to deliver repeated, predictable precision. Manufacturers may obtain numerical repeatability while removing human error by using lasers. The increased performance and speed boosts worker productivity while lowering maintenance requirements, downtime, and production costs.

Improved Diagnostics To Avoid Large-Scale Mistakes

When producing vast numbers of identical items, even minor misalignment might result in catastrophic difficulties that drive up overhead expenses. Unfortunately, alignment issues are almost always invisible to the human eye.

Diagnostic specialists may use industrial shaft alignment equipment to uncover big and little faults that might otherwise go unnoticed. When an emergency occurs, laser trackers may help manufacturers deal with it; nevertheless, they are most valuable for avoiding catastrophes in the first place. Producers may prevent issues before they lead to mass-replication of faulty items by undertaking frequent diagnostic tests. For more information visit our Website.